XT SERIES GATE VALVES

Fields containing oil with high viscosity (also referred to as heavy oil) require Enhanced Oil Recovery (EOR) methods such as Steam Assisted Gravity Drainage (SAGD). The injection of steam into the reservoir requires reliable equipment suitable for elevated temperatures. The Valveworks USA Extreme Temperature (XT) series consists of a lineup of gate valves with industry-leading sealing technology, reliable and proven designs that are engineered and manufactured to meet the requirements of API 6A while providing optimal performance in elevated temperature environments up to 650°F (345°C).

This series of gate valves offers the user several options depending on the specific application including achieving a positive seal at wellbore/flowline pressures ranging from zero to 15,000 PSI. XT series gate valves are full-bore valves. This allows for downhole tools to be passed through the wellhead and reduces turbulent flow. XT series valves are similar to each other in design with only slight variations across the lineup, offering a high percentage of parts interchangeability, giving you an efficiency-driven advantage in the management and maintenance of your gate valve fleet and providing optimal lifecycle management integrity.

This document provides an in-depth look at the details of this series of gate valves and explains the features, benefits, characteristics, dimensional & technical data and other valuable information needed to determine which valve provides an optimal solution for your specific application.

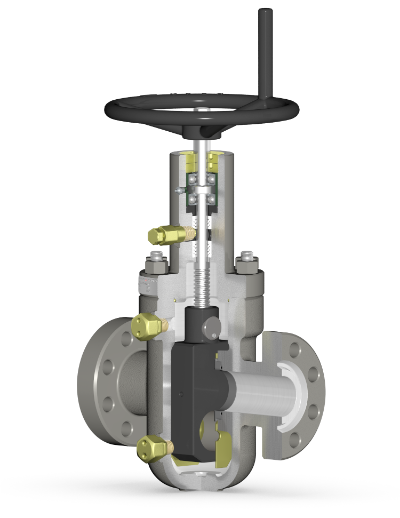

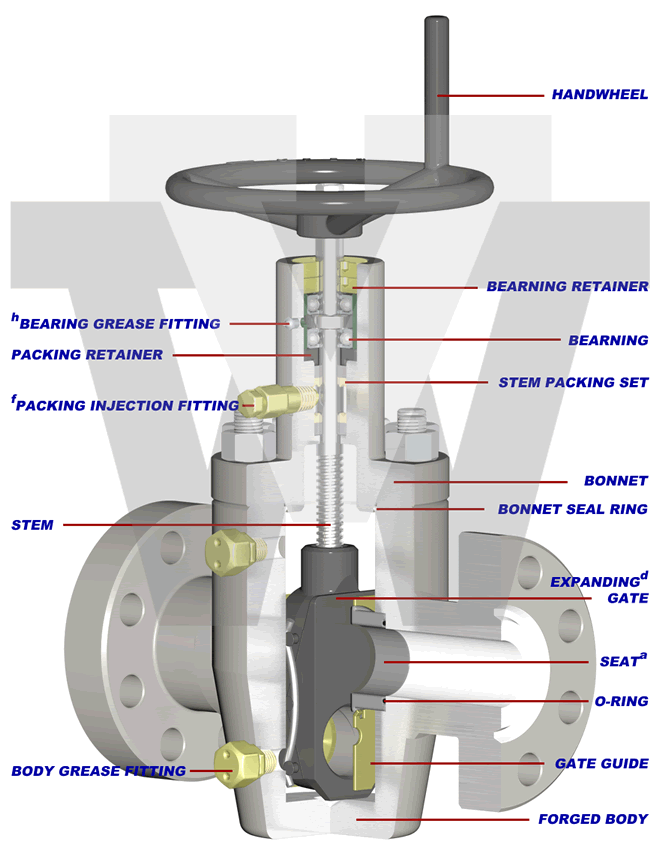

MODEL XT1DS – UNIDIRECTIONAL, EXPANDING GATE, CAST BODY

d) See engineering note titled “Expanding Gate Assembly Operation Explained” for details.

f) Stuffing box can be repacked via injectable packing while the valve is in service up to the rates working pressure.

h) Valve bonnet equipped with grease port(s) and fitting(s) for bearing lubrication.

*The actual product may vary slightly from shown schematic due to engineering approved variation

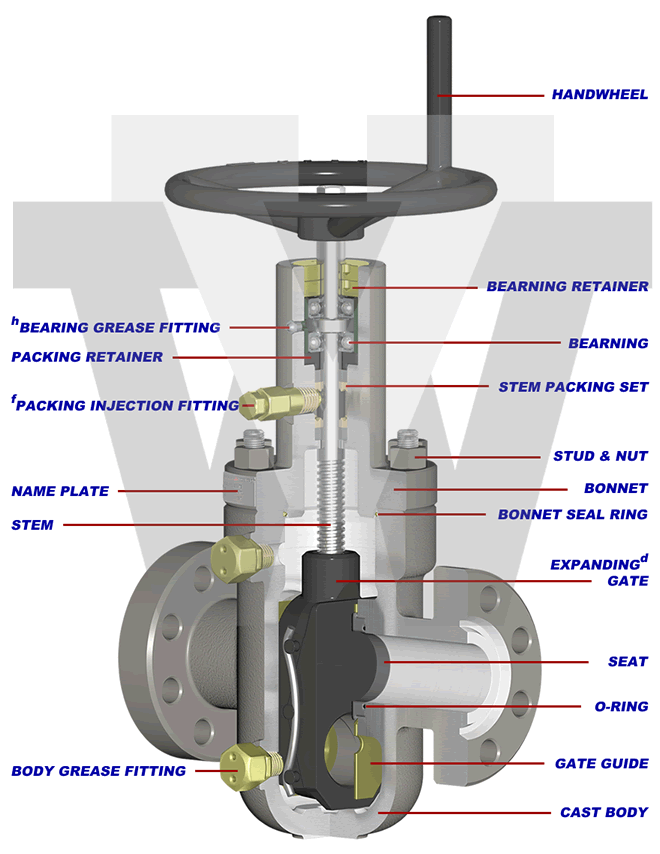

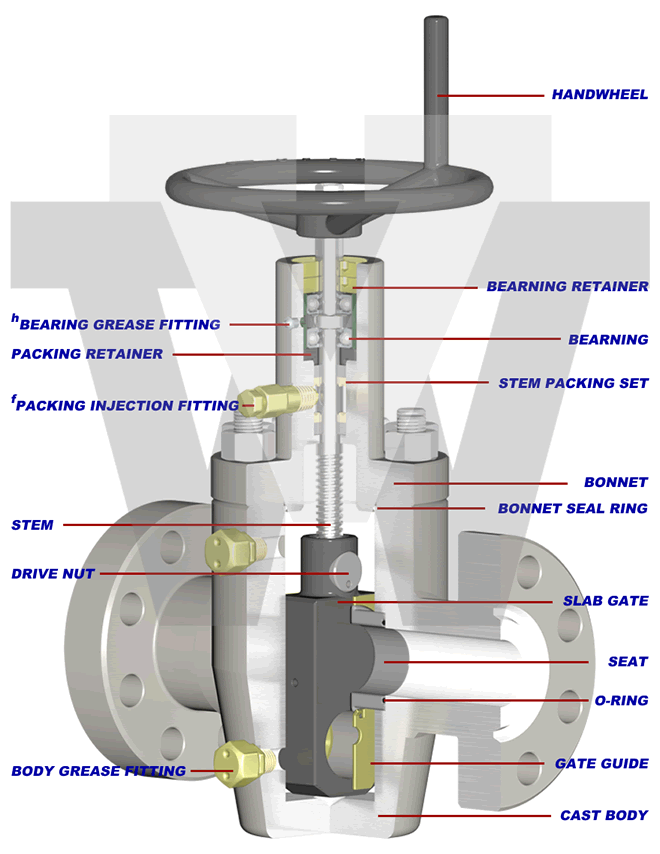

MODEL XT1SG – BIDIRECTIONAL, SLAB GATE, CAST BODY

h) Valve bonnet equipped with grease port(s) and fitting(s) for bearing lubrication.

*The actual product may vary slightly from shown schematic due to engineering approved variation

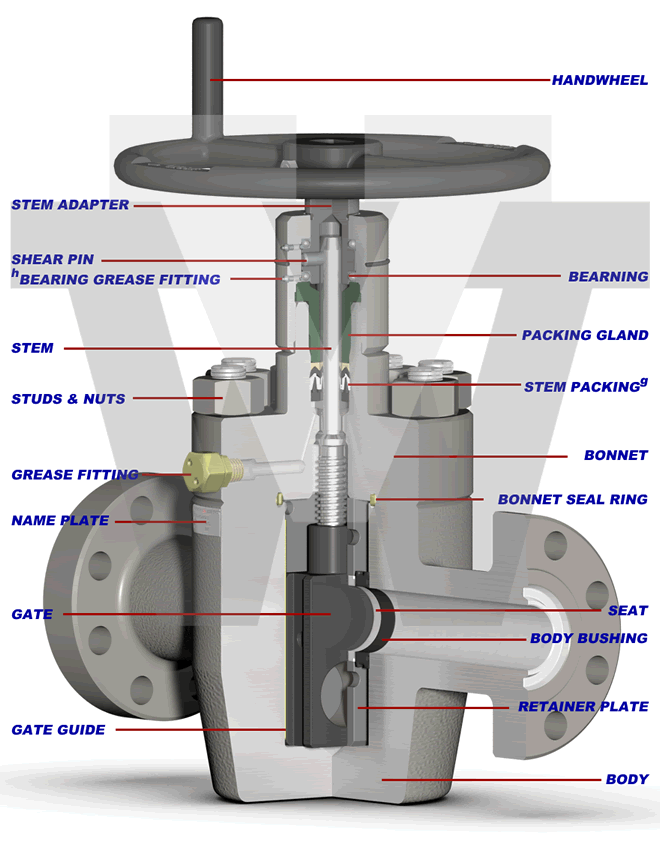

MODEL XT1RC DS – UNIDIRECTIONAL, EXPANDING GATE, FORGED BODY

d) See engineering note titled “Expanding Gate Assembly Operation Explained” for details.

f) Stuffing box can be repacked via injectable packing while the valve is in service up to the rates working pressure.

h) Valve bonnet equipped with grease port(s) and fitting(s) for bearing lubrication.

*The actual product may vary slightly from shown schematic due to engineering approved variation

MODEL XT1RC SG – BIDIRECTIONAL, SLAB GATE, FORGED BODY

h) Valve bonnet equipped with grease port(s) and fitting(s) for bearing lubrication.

*The actual product may vary slightly from shown schematic due to engineering approved variation

MODEL XT2 – BIDIRECTIONAL, SLAB GATE, FORGED BODY

h) Valve bonnet equipped with grease port and fitting for bearing lubrication.

*The actual product may vary slightly from shown schematic due to engineering approved variation

DISCLAIMER: THE ACTUAL PRODUCT MAY VARY SLIGHTLY FROM SHOWN SCHEMATIC DUE TO ENGINEERING APPROVED VARIATION.

WARNING: L7M / B7M STUDS CANNOT BE SUBSTITUED FOR L7 / B7 STUDS.

TABLE 1 – PRODUCT FEATURES

| MODEL XT GATE VALVE VARIATIONS | |||||

|---|---|---|---|---|---|

| FEATURES | XT1DS | XT1SG | XT1RC DS | XT1RC SG | XT2 |

| Flow Direction | Unidirectionala | Bidirectional | Unidirectionala | Bidirectional | Bidirectional |

| AvailableBore Size & Rated Working Pressure (psi)b | 2-1/16" 2K,3K,5K 2-9/16" 2K,3K,5K 3-1/8" 2K,3K,5K 4-1/16" 2K,3K,5K 5-1/8" 2K,3K,5K |

2-1/16" 2K,3K,5K 2-9/16" 2K,3K,5K 3-1/8" 2K,3K,5K 4-1/16" 2K,3K,5K 5-1/8" 2K,3K,5K |

2-1/16" 2K,3K,5K 2-9/16" 2K,3K,5K 3-1/8" 2K,3K,5K 4-1/16" 2K,3K,5K 5-1/8" 2K,3K,5K |

2-1/16" 2K,3K,5K 2-9/16" 2K,3K,5K 3-1/8" 2K,3K,5K 4-1/16" 2K,3K,5K 5-1/8" 2K,3K,5K |

1-13/16" 10K,15K 2-1/16" 5K,10K,15K 2-9/16" 5K,10K,15K 3-1/8" 3K,5K 3-1/16" 10K,15K 4-1/16" 3K,5K,10K |

| Available PSLc | 1,2 | 1,2 | 1,2,3,3G | 1,2,3,3G | 1,2,3,3G |

| Available PR | 1,2,2F | 1,2,2F | 1,2,2F | 1,2,2F | 1,2,2F |

| Material Classes | AA,BB,CC,DD,EE,FF | AA,BB,CC,DD,EE,FF | AA,BB,CC,DD,EE,FF,HH | AA,BB,CC,DD,EE,FF,HH | AA,BB,CC,DD,EE,FF,HH |

| Valve Body | Cast | Cast | Forged | Forged | Forged |

| Gate Type | Expandingd | Slab | Expandingd | Slab | Slab |

| Sealing Action | Mechanical | Pressure-Energized | Mechanical | Pressure-Energized | Pressure-Energized |

| Operation Type | Manuale | Manuale | Manuale | Manuale | Manuale |

| Bore Type | Full-Bore | Full-Bore | Full-Bore | Full-Bore | Full-Bore |

| Gate/Seat Seal | Metal to Metal | Metal to Metal | Metal to Metal | Metal to Metal | Metal to Metal |

| Stem Type | Non-rising | Non-rising | Non-rising | Non-rising | Non-rising |

| Stem Packing Type | Grafoil®-V | Grafoil®-V | Grafoil®-V | Grafoil®-V | Spring-Energized |

| Repacking | Yesf | Yesf | Yesf | Yesf | Yesg |

| Thrust Bearings | 2 | 2 | 2 | 2 | 2 |

| Body Lubrication Fittings | 2h | 2h | 2h | 2h | 1 |

| Body/Bonnet Connection | Bolted | Bolted | Bolted | Bolted | Bolted |

| End Connections | Flanged (RTJ) | Flanged (RTJ) | Flanged (RTJ) | Flanged (RTJ) | Flanged (RTJ) |

| Temperature Range | -50°F (-46°C) Thru 650°F (345°C) | -50°F (-46°C) Thru 650°F (345°C) | -50°F (-46°C) Thru 650°F (345°C) | -50°F (-46°C) Thru 650°F (345°C) | -2°0F (-29°C) Thru 350°F (180°C) |

a. Equipped with a non-sealing seat on the upstream side. See engineering note titled “Model XT1DS & Model XT1RC DS” for details.

b. 2 1/16″ x 1 13/16″, 3 1/8″ x 3 3/16″, 4 1/16″ x 4 1/8″, and 4 1/16″ x 4 1/4″ available upon request.

c. Product Specification Level

d. See engineering note titled “Expanding Gate Assembly Operation Explained” for details.

e. Also referred to as “HANDWHEEL OPERATED”

f. Stuffing box can be repacked via injectable packing while the valve is in service up to the rated working pressure.

g. Stuffing box can be repacked via back seat while the valve is in service up to the rated working pressure.

h. Valve bonnet equipped with grease port(s) and fitting(s) for bearing lubrication.

ENGINEERING NOTES

Expanding Gate Assembly Operation Explained – The expanding gate assembly consists of two main components: the gate (major) and the segment (minor). These components are assembled together using precision machined pins and high-quality, precision formed and treated Nickel-Chromium alloy springs. When the valve is manually operated, the gate and segment act one against the other by means of a dual expanding wedge when the valve is either fully opened or fully closed. This expansion effect of the gate assembly against the valve seats, through parallel faces of the gate assembly, provides a strong and positive seal against pulsations and vibrations created by flow conditions. This is advantageous when attempting to accomplish a positive seal in both high and low pressure conditions.

Model XT1DS & Model XT1RC DS – These models are unidirectional gate valves equipped with an expanding gate assembly and a sealing seat in the downstream seat pocket. The upstream seat pocket is equipped with a non-sealing seat assembly. This allows pressure to bypass the upstream seat, equalize throughout the valve body, and only seal against the downstream seat assembly as the original Model M was intended. All model XT1DS valves are marked with a flow direction arrow for accurate installation.

NOTE: When bidirectional operation is required, a slab gate valve is necessary. XT1 Series expanding gate valves (Model XT1DS and Model XT1RC DS) are not designed for bidirectional operation.

Pressure Testing – XT1 series gate valves are not intended to be tested through the body lubrication fittings. These fittings are designed for lubrication purposes only. Shell tests and gate/seat tests shall be conducted from the end/outlet connection by qualified personnel only.

TABLE 2 – TEMPERATURE RATING

| CLASSIFICATION | OPERATING TEMP. RANGE |

|---|---|

| L | -50°F (-46°C) TO 180°F (82°C) |

| P | -20°F (-29°C) TO 180°F (82°C) |

| X | 0°F (-18°C) TO 350°F (180°C) |

| Y | 0°F (-18°C) TO 650°F (345°C) |

TABLE 3 – MATERIAL REQUIREMENTS

| MINIMUM MATERIAL REQUIREMENTS | |||

|---|---|---|---|

| MATERIAL CLASS | BODY, BONNET END & OUTLET CONNECTIONS | PRESSURE-CONTROLLING PARTS & STEMS | |

| AA | General Service | Carbon or Low-Alloy Steel | Carbon or Low-Alloy Steel |

| BB | General Service | Carbon or Low-Alloy Steel | Stainless Steel |

| CC | General Service | Stainless Steel | Stainless Steel |

| DD | Sour Servicea | Carbon or Low-Alloy Steelb | Carbon or Low-Alloy Steelb |

| EE | Sour Servicea | Carbon or Low-Alloy Steelb | Stainless Steelb |

| FF | Sour Servicea | Stainless Steelb | Stainless Steelb |

| HH | Sour Servicea | CRAacd | CRAacd |

VALVEWORKS USA DESCRIPTION KEY

| GV, | 6A, | MOD MDS, | EXP GATE, | 2 1/16" | 5M | FE | DD-NL- | KU- | 1- | 2, | HWO | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GATE VALVE | ||||||||||||

| API SPECIFICATION | ||||||||||||

| VALVEWORKS USA MODEL | ||||||||||||

| GATE TYPE | ||||||||||||

| BORE SIZE (NOMINAL) | ||||||||||||

| RATED WORKING PRESSURE | ||||||||||||

| END CONNECTION | ||||||||||||

| MATERIAL CLASS | ||||||||||||

| TEMPERATURE RATING/CLASSIFICATION | ||||||||||||

| PSL | ||||||||||||

| PR | ||||||||||||

| OPERATION TYPE |

ABBREVIATION KEY

- MSG = Model M Slab Gate

- MDS = Model M Unidirectional

- MRC SG = Model M Round Cavity Slab Gate

- MRC DS = Model M Round Cavity Unidirectional

- HWO = Handwheel Operated (manual)

- EXP = Expanding

- SG = Slab Gate

- FE = Flanged End

- RTJ = Ring Type Joint

- PSL = Product Specification Level

- PR = Performance Requirement

- LP = Line Pipe

- STC = Casing Short Thead

- LC = Casing Long Thead

- EU = Tubing, Ecternal Upset

- CRA = Corrosion-resistant Alloy

- XYL = Xylan®

- HF = Hardfaced

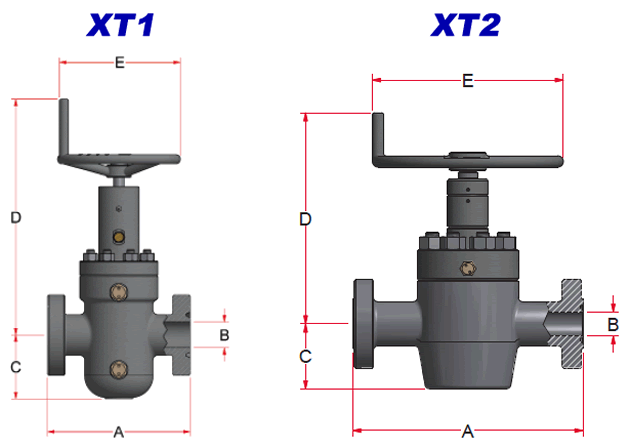

DIMENSION TABLE KEY

| Key | Description |

|---|---|

| A | Face to Face |

| B | Valve Bore Size (Nominal) |

| C | Bore Centerline to Bottom |

| D | Bore Centerline to Top |

| E | Handwheel Diameter |

| NT | Number of Turns |

| RJ | Ring Joint |

| TS | Thread Size |

| BBS | Bonnet Stud Size |

| N | Number of Studs |

| WT | Approximate Weight |

| HT | Handwheel Operating Torque |

FLANGED GATE VALVES

| SIZE | WP (PSI) | A | B | C | D | E | NT | RJ | BSS | N | WT(LBS) | HT(FT-LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 21/16 | 2K | 11 5/8 | 2 1/16 | 5 1/4 | 19 1/2 | 10 | 14 | R-23 | 5/8 | 8 | 120 | 32 |

| 3K | 14 5/8 | 2 1/16 | 5 1/2 | 19 5/8 | 13 | 14 | R-24 | 7/8 | 8 | 180 | 40 | |

| 5K | 14 5/8 | 2 1/16 | 5 1/2 | 19 5/8 | 13 | 14 | R-24 | 7/8 | 8 | 180 | 57 | |

| 29/16 | 2K | 13 1/8 | 2 9/16 | 6 3/8 | 20 1/2 | 13 | 16 1/2 | R-26 | 5/8 | 8 | 180 | 37 |

| 3K | 16 5/8 | 2 9/16 | 6 5/8 | 20 7/8 | 16 | 16 1/2 | R-27 | 7/8 | 8 | 220 | 49 | |

| 5K | 16 5/8 | 2 9/16 | 6 5/8 | 20 7/8 | 16 | 16 1/2 | R-27 | 7/8 | 8 | 220 | 66 | |

| 31/8 | 2K | 14 1/8 | 3 1/8 | 7 5/8 | 22 7/8 | 13 | 20 3/4 | R-31 | 7/8 | 8 | 220 | 48 |

| 3K | 17 1/8 | 3 1/8 | 7 5/8 | 23 | 16 | 20 3/4 | R-31 | 1 | 8 | 300 | 65 | |

| 5K | 18 5/8 | 3 1/8 | 7 5/8 | 23 | 16 | 20 3/4 | R-35 | 1 | 8 | 340 | 90 | |

| 41/16 | 2K | 17 1/8 | 4 1/16 | 9 5/8 | 26 1/2 | 16 | 24 3/4 | R-37 | 1 | 8 | 360 | 81 |

| 3K | 20 1/8 | 4 1/16 | 9 5/8 | 26 5/8 | 20 | 24 3/4 | R-37 | 1 3/8 | 8 | 520 | 67 | |

| 5K | 21 5/8 | 4 1/16 | 9 5/8 | 26 5/8 | 20 | 24 3/4 | R-39 | 1 3/8 | 8 | 560 | 130 | |

| 51/8 | 2K | 22 1/2 | 5 1/8 | 11 3/4 | 30 | 24 | 30 1/4 | R-41 | 1 3/8 | 8 | 770 | 150 |

| 3K | 24 1/8 | 5 1/8 | 11 3/4 | 30 | 24 | 30 1/4 | R-41 | 1 3/8 | 8 | 810 | 210 | |

| 5K | 28 5/8 | 5 1/8 | 11 3/4 | 30 | 24 | 30 1/4 | R-41 | 1 3/8 | 8 | 940 | 366 |

All dimensions are in inches.

THREADED GATE VALVES

| SIZE | WP (PSI) | A | B | C | D | E | NT | RJ | BSS | N | WT(LBS) | HT(FT-LBS) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 13/16 | 10K | 18 1/4 | 1 13/16 | 5 13/16 | 18 13/16 | 16 | 11 3/4 | BX-151 | 1 1/8 | 8 | 270 | 59 |

| 15K | 18 | 1 13/16 | 6 13/16 | 18 13/16 | 16 | 11 3/4 | BX-151 | 1 1/4 | 8 | 275 | 89 | |

| 2 1/16 | 5K | 14 5/8 | 2 1/16 | 5 7/8 | 18 7/8 | 14 | 12 | R-24 | 7/8 | 8 | 189 | 32 |

| 10K | 20 1/2 | 2 1/16 | 5 13/16 | 18 13/16 | 16 | 12 1/2 | BX-152 | 1 1/8 | 8 | 275 | 66 | |

| 15K | 19 | 2 1/16 | 6 1/8 | 18 13/16 | 16 | 12 1/2 | BX-152 | 1 1/4 | 8 | 350 | 103 | |

| 2 9/16 | 5K | 16 5/8 | 2 9/16 | 6 5/16 | 19 1/2 | 16 | 16 1/4 | R-27 | 1 | 8 | 275 | 49 |

| 10K | 22 1/4 | 2 9/16 | 6 7/8 | 19 5/8 | 20 | 16 | BX-153 | 1 1/4 | 8 | 485 | 111 | |

| 15K | 21 | 2 9/16 | 7 13/16 | 22 7/8 | 20 | 15 1/2 | BX-153 | 1 1/8 | 12 | 520 | 221 | |

| 3 1/8 | 3K | 17 1/8 | 3 1/8 | 7 13/16 | 20 1/2 | 16 | 17 1/2 | R-31 | 1 1/8 | 8 | 337 | 40 |

| 5K | 18 5/8 | 3 1/8 | 7 9/16 | 20 1/2 | 16 | 17 1/2 | R-35 | 1 1/8 | 8 | 355 | 67 | |

| 3 1/16 | 10K | 24 3/8 | 3 1/16 | 8 1/8 | 22 | 23 | 17 1/2 | BX-154 | 1 3/8 | 8 | 550 | 140 |

| 15K | 23 9/16 | 3 1/16 | 9 1/8 | 25 5/8 | 23 | 15 1/2 | BX-154 | 1 3/8 | 12 | 914 | 308 | |

| 4 1/16 | 3K | 20 1/8 | 4 1/16 | 9 5/16 | 22 | 20 | 24 1/4 | R-37 | 1 1/4 | 8 | 498 | 70 |

| 5K | 21 5/8 | 4 1/16 | 9 13/16 | 22 | 20 | 23 1/4 | R-39 | 1 1/4 | 8 | 550 | 113 | |

| 10K | 26 3/8 | 4 1/16 | 10 1/8 | 28 3/4 | 24 | 23 1/4 | BX-155 | 1 5/8 | 8 | 950 | 258 |