Casing Hangers

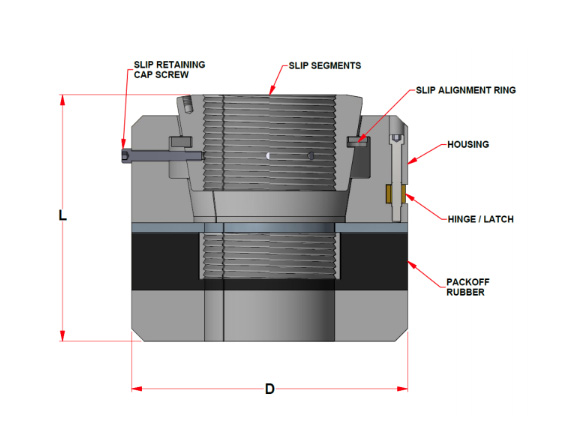

C-29 Casing Hanger

| Nominal Size (Inches) | "D" (Inches) | "L" (Inches) | Approximate Weight (LBS/KG) |

|---|---|---|---|

| 11 x 4 - 1/2 | 10 - 13/16 | 9 - 5/8 | 138/63 |

| 11 x 5 | 10 - 13/16 | 9 - 5/8 | 124/56 |

| 11 x 5 - 1/2 | 10 - 13/16 | 9 - 5/8 | 120/64 |

| 11 x 6 - 5/8 | 10 - 13/16 | 9 - 5/8 | 140/64 |

| 11 x 7 | 10 - 13/16 | 9 - 5/8 | 88/40 |

| 11 x 7 - 5/8 | 10 - 13/16 | 9 - 5/8 | 115/52 |

| 13 - 5/8 x 5 | 13 - 7/16 | 9 - 5/8 | 219/99 |

| 13 - 5/8 x 5 - 1/2 | 13 - 7/16 | 9 - 5/8 | 217/98 |

| 13 - 5/8 x 7 | 13 - 7/16 | 9 - 5/8 | 189/86 |

| 13 - 5/8 x 7 - 5/8 | 13 - 7/16 | 9 - 5/8 | 175/79 |

| 13 - 5/8 x 8 - 5/8 | 13 - 7/16 | 9 - 5/8 | 146/66 |

| 13 - 5/8 x 9 - 5/8 | 13 - 7/16 | 9 - 5/8 | 121/55 |

| 16 - 3/4 x 9 - 5/8 | 16 - 9/16 | 8 - 7/8 | 404/183 |

| 16 - 3/4 x 10 - 3/4 | 16 - 9/16 | 8 - 7/8 | 351/159 |

| 21-1/4 X 13-3/8 | 8 - 7/8 | 403/183 | |

| 20 - 3/4 X 13 - 3/8 | 8 - 7/8 | 403 183 |

Valveworks USA C-29 casing hanger is combined in a single unit that incorporates pack-off, slip bowl, and slips. The C-29 casing hanger is designed to suspend medium to heavy casing loads and provides automatic pack-off sealing by energizing the seal when the string weight is applied. The C-29 casing hanger’s controlled friction reduces casing deflection and provides a hanging capacity of 80% of the casing’s body yield. The casing load is distributed equally to the bowl of the casing head due to even engagement of the slips. “Note: To maintain an equally distributed casing load, the slip segments may require adjustment prior to the string weight being applied.” Available in Product Specification Level (PSL) 1, 2, and 3 with PR-2 design validation. Available in Material Class AA and Material Class DD-NL.

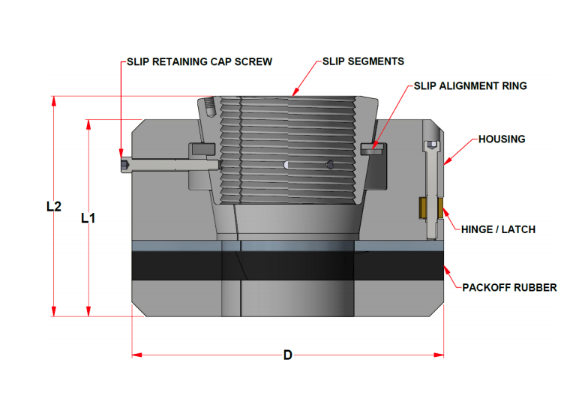

C-22 Casing Hanger

| Nominal Size (Inches) | "D" (Inches) | "L1" (Inches) | "L2" (Inches) | Approximate Weight (LBS/KG) |

|---|---|---|---|---|

| 9 x 4 - 1/2 | 8-11/16 | 8-1/16 | 45 / 20 | |

| 9 X 5 | 8-11/16 | 8-1/16 | 40 / 19 | |

| 9 X 5-1/2 | 8-11/16 | 7-5/8 | 34 / 15 | |

| 11 X 4-1/2 | 10-13/16 | 6-13/16 | 7-5/8 | 100 / 45 |

| 11 x 5 | 10-13/16 | 6-13/16 | 7-5/8 | 95 / 43 |

| 11 x 5-1/2 | 10-13/16 | 6-13/16 | 7-5/8 | 89 / 40 |

| 11 x 6-5/8 | 10-13/16 | 6-13/16 | 7-5/8 | 75 / 34 |

| 11 x 7 | 10-13/16 | 6-13/16 | 8-1/16 | 75 / 34 |

| 11 x 7-5/8 | 10-13/16 | 8-1/16 | 60 / 27 | |

| 13-5/8 x 5 | 13 - 7/16 | 8-1/16 | 167 / 76 | |

| 13-5/8 x 5-1/2 | 13 - 7/16 | 8-1/16 | 160 / 73 | |

| 13-5/8 x 7 | 13 - 7/16 | 8-1/16 | 152 /69 | |

| 13-5/8 x 7-5/8 | 13 - 7/16 | 8-1/16 | 140 / 64 | |

| 13-5/8 x 8-5/8 | 13 - 7/16 | 8-1/16 | 125 / 57 | |

| 13-5/8 x 9-5/8 | 13 - 7/16 | 8-1/16 | 108 / 49 | |

| 16-3/4 x 9-5/8 | 16-9/16 | 9 | 299 / 136 | |

| 16-3/4 x 10-3/4 | 16-9/16 | 9 | 260 / 118 | |

| 21-1/4 x 13-3/8 | 20-1/16 | 9 | 310 / 141 |

Valveworks USA C-22 casing hanger is combined in a single unit that incorporates pack-off, slip bowl, and slips. The C-22 casing hanger is designed to suspend medium casing loads and provides automatic pack-off sealing by energizing the seal when the string weight is applied. The C-22 casing hanger’s controlled friction reduces casing deflection and provides a hanging capacity of 50% of the casing’s body yield. The casing load is distributed equally to the bowl of the casing head due to even engagement of the slips. “Note: To maintain an equally distributed casing load, the slip segments may require adjustment prior to the string weight being applied.” Available in Product Specification Level (PSL) 1, 2, and 3 with PR-2 design validation. Available in Material Class AA and Material Class DD-NL.

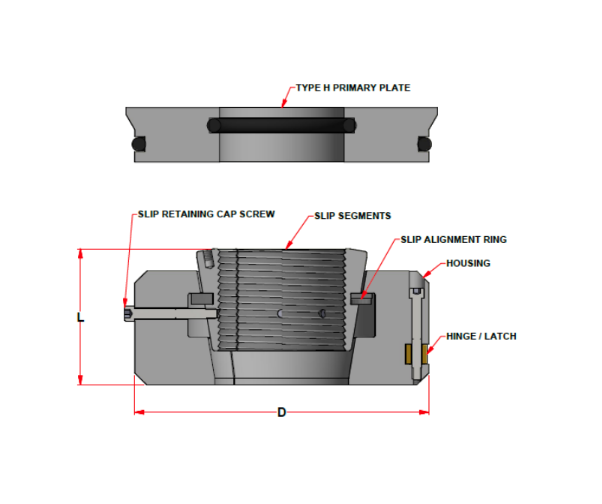

C-21 Casing Hanger

| Nominal Size (Inches) | "D" (Inches) | "L" (Inches) | Approximate Weight (LBS/KG) |

|---|---|---|---|

| 9 x 4 - 1/2 | 8-11/16 | 5-1/8 | 64 / 29 |

| 9 X 5 | 8-11/16 | 5-1/8 | 56 / 26 |

| 9 X 5-1/2 | 8-11/16 | 5-1/8 | 50 / 23 |

| 11 X 4-1/2 | 10-13/16 | 5 | 123 / 56 |

| 11 x 5 | 10-13/16 | 5 | 108 / 49 |

| 11 x 5-1/2 | 10-13/16 | 5 | 106 / 48 |

| 11 x 6-5/8 | 10-13/16 | 5 | 84 / 38 |

| 11 x 7 | 10-13/16 | 5 | 76 / 34 |

| 11 x 7-5/8 | 10-13/16 | 5 | 59 / 27 |

| 13-5/8 x 5 | 13 - 7/16 | 5 | 193 / 88 |

| 13-5/8 x 5-1/2 | 13 - 7/16 | 5 | 191 / 87 |

| 13-5/8 x 7 | 13 - 7/16 | 5 | 161 / 73 |

| 13-5/8 x 7-5/8 | 13 - 7/16 | 5 | 151 / 68 |

| 13-5/8 x 8-5/8 | 13 - 7/16 | 5 | 123 / 56 |

| 13-5/8 x 9-5/8 | 13 - 7/16 | 5 | 101 / 46 |

| 16-3/4 x 9-5/8 | 16-9/16 | 229 / 104 | |

| 16-3/4 x 10-3/4 | 16-9/16 | 201 / 91 | |

| 21-1/4 x 13-3/8 | 20-1/16 | 283 / 129 |

Valveworks USA C-21 casing hanger is combined in a single unit that incorporates a slip bowl and slips. The C-21 casing hanger is designed to suspend light to medium casing loads. The C-21 casing hanger’s controlled friction reduces casing deflection and provides a hanging capacity of 50% of the casing’s body yield. The casing load is distributed equally to the bowl of the casing head due to even engagement of the slips. “Note: To maintain an equally distributed casing load, the slip segments may require adjustment prior to the string weight being applied.” Available in Product Specification Level (PSL) 1, 2, and 3 with PR-2 design validation. Available in Material Class AA and Material Class DD-NL.